The Safest Way to Load Spotted Trailers and Tankers

Manually Positioned Jack

At StabilJack we have engineered exceptional products that increase the safety of your employees. Our models are ergonomic and

easy to use.

Spotter-Truck Positioned Jack

Eliminate upending and overturned trailers, collapsed landing gear and aggressive pullouts.

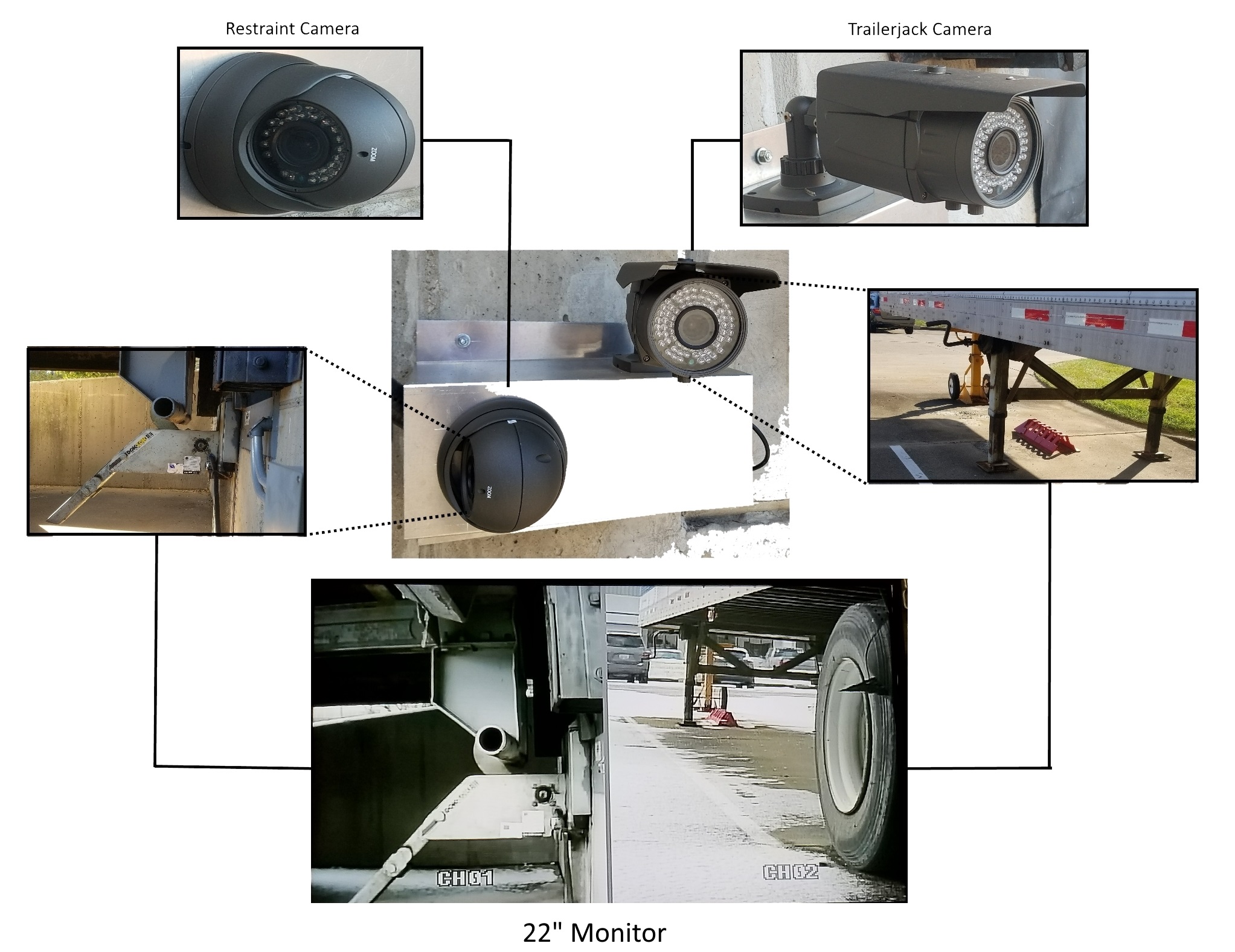

Verification System

Decrease verification time and boots on the ground. Ensure the restraint and StabilJack are in place from inside the facility before loading and unloading begins.

At Last, World Class Trailer Safety

We understand you are looking for a true solution to stabilizing your Spotted Trailers and Tankers. We look forward to learning about your site in order to recommend the best model for your needs. Contact us to arrange a time to discuss how a StabilJack model and Verification System can increase your site safety and efficiency.

We have a dedicated staff of professional experts available to assist you. Please contact us at the phone number below or fill out the form and someone will contact you directly.

CALL US TODAY at 1.866.641.7222